Our Products

Explore the high-quality products we manufacture by clicking this button. You'll be directed to our Products page.

Read MoreAbout Us

Learn more about our company and our mission by clicking this button. You'll be directed to our About Us page.

Read MoreContact Us

If you have any questions, comments, or concerns, please don't hesitate to get in touch.

Read More

About Us

TSB is a highly reputed manufacturer and supplier of top-quality plastic granules. We believe in delivering top-quality products, with a focus on innovation, sustainability, and customer satisfaction. These three principles drive everything we do.

-

Commitment to Quality

we are committed to providing top-quality products that meet our client's specific needs. We use advanced manufacturing processes and employ strict quality control measures to ensure that our products meet the highest standards. Our team conducts rigorous checks on all our plastic raw materials and recycled plastic granules before dispatching them to the client.

-

Diverse Product Range

We offer a diverse range of high-quality plastic compounds and masterbatch, catering to a variety of industries. Our PE compound line includes HDPE pipe granules, HDPE OFC cable compound (optical), PE Ariel bunch black compound, and PE power cable compound (high voltage). We also provide PBT resin and PBT compound, which are widely used in applications such as electrical components, automotive parts, and consumer goods. Additionally, we offer antioxidant stabilizer and UV stabilizer masterbatch solutions, designed to enhance the properties of plastics.

-

Trusted Reputation

With an unwavering commitment to integrity and transparency, which has helped us establish ourselves as a trusted name in the market. We are dedicated to providing our clients with top-quality products and reliable service, making us a preferred supplier in the industry. Our clients trust us to deliver on our promises, and we work hard to ensure their satisfaction with every interaction.

Our Products

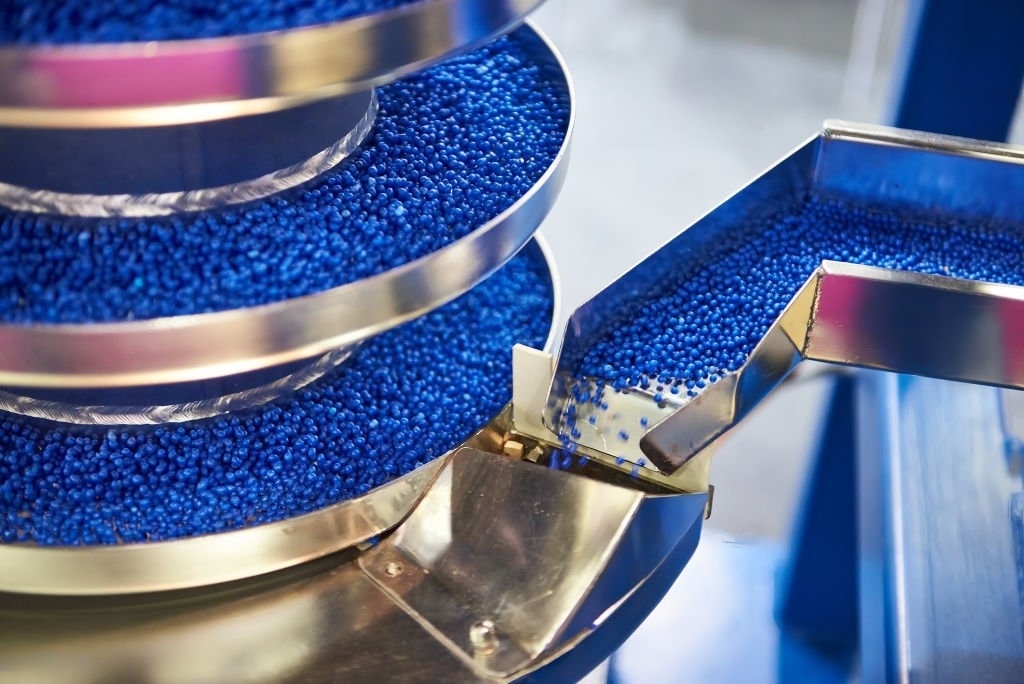

PE Compounds

Polyethylene (PE) is a light, versatile synthetic resin made from the polymerization of ethylene. Our PE compounds are generally based on polyethylene or co-polymers of polyethylene suitably modified to client specifications. PE compounds are one of our main product lines. We offer a diverse range of high-quality PE compounds, including HDPE pipe granules, HDPE OFC cable compound, PE Ariel bunch black compound, and PE power cable compound.

PBT Compounds

Polybutylene terephthalate (PBT) is a thermo-plastic engineering polymer that is used as an insulator in the electrical and electronics industries. PBT resists solvents, shrinks very little during forming, is mechanically strong. PBT is used for housings in electrical engineering, but also in automotive construction as plug connectors and in households for example in showerheads or irons.

Masterbatches

A masterbatch is a plastics formulation that contains additives that are essential for the appearance and performance of the final product. We offer a variety of masterbatch solutions, including antioxidant stabilizer and UV stabilizer. Our masterbatch products are designed to meet the specific needs of our clients and enhance the performance of their plastic products.

HDPE Compounds

HDPE is a thermoplastic polymer made from the monomer ethylene. HDPE compounds are made by mixing HDPE resin with additives, fillers, or pigments to improve its properties or enhance its performance in specific applications. HDPE compounds can be customized to meet specific performance requirements for different applications, such as pipes, sheets, bottles, and films. They are known for their high strength, stiffness, and toughness.

PBAT Compounds

PBAT polymer has excellent mechanical performance with good heat resistance and outstanding processability, allowing it to be variously processed on conventional blown film plants. Polybutylene adipate terephthalate is also an environment-friendly polyester. Polybutylene adipate terephthalate is a semi-aromatic, biodegradable thermoplastic copolyester that combines some of the beneficial attributes of synthetic and biobased polymers. PBAT polymer has good ductility, elongation at break, heat resistance, and biodegradability.

BLOWING AGENT (ADCL)

Azodicarbonamide (also known as ADC or ADCL) is the most popular chemical blowing agent. Generally, AC is orange to pale yellow, crystalline solid with a decomposition temperature of 201-205 C (in air).Unlike a number of other chemical blowing agents, AC is self-extinguishing when flame is removed. The decomposition residues are odorless, non-toxic, non-coloring and, non-straining. The particle size and distribution can be controlled with widely different ranges.

Impact Modifier

Chlorinated PolyEthylene (CPE) is produced by combining chlorine and polyethylene in a process which is saturated. Linear high molecular structure enables CPE with superior physical and chemical performances.CPE has been widely used in plastics and rubber applications It Is a new type of PVC impact modifier independently developed by our company.

Polymer Additives

It is mainly used to produce outdoor PVC applications, such as PVC window profile , PVC pipe and pipe fitting, PVC fence, PVC siding and decking, PVC panel and so on. It should be stored in cool and dry surroundings with shelf life of two years, it can be still used if qualified by inspection after shelf life.

Dicumyl Peroxide (DCP)

DCP (dicumyl peroxide), is a white crystal which has C18H2202 as chemical formula. This dialkyl peroxide is used for the (co)polymerization of styrene, besides it is used to crosslink polymers and elastomers. Further it finds its application as flame retardant synergist in EPS. Dicumyl Peroxide is also known as Diisopropylbenzene peroxide, Bis(a,a-dimethylbenzyl) peroxide and Dicumene hydroperoxide.

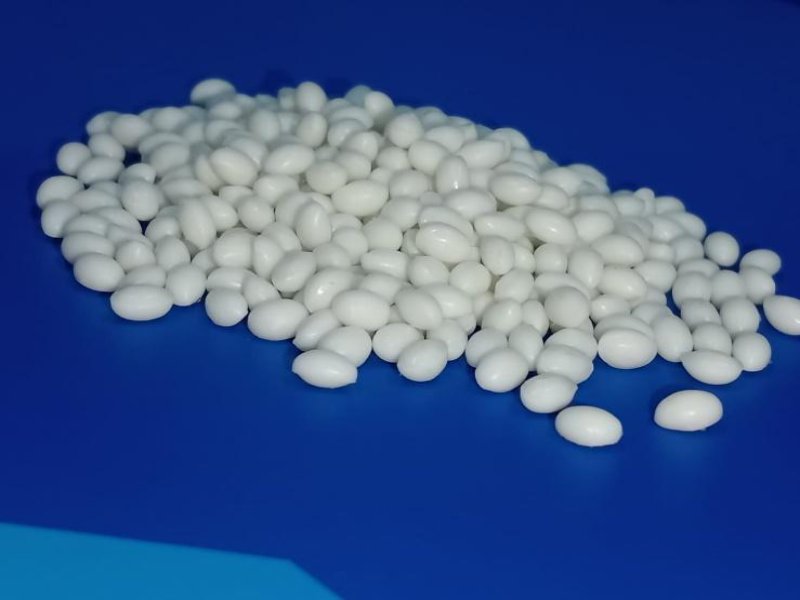

Silicone Additive

Silicone additive of TSB series, appearing as white pellet and powder, are made of polyalkoxysilane with high molecular weight, and used as processing lubricant for plastic. Silicone additive overcomes the disadvantages in properties and productions which traditional additive like simethicone may possess. Silicone additive of TSB series are safe, stable, convenient, and has good dispersity in resin and its characteristics are showed as below:

Biodegradable Compounds

Biodegradable Compound is one compostable random copolymer produced through a polycondensation reaction, consisting of a copolyester of and terephthalate acid. The compostability of fulfills the requirements of DIN V 54900-1, EN 13432, ASTM D 6400 standard, and the material meets the U.S. FDA food safety standard. The high molecular weight of makes it possible for blown or cast film, alone or blended with other materials.

PLA COMPOUNDS

PLA is a biobased polymer derived from natural resources and offers a significant reduction in carbon footprint compared to oil-based plastics. Luminy LX175 is a high viscosity, low flow, amorphous, transparent Standard PLA can be processed on conventional extrusion equipment and can be used as neat resin or as part of a compound to further optimize overall material properties.